Erosion Resistant Screen Technology

Delta Screens collaborated with Chevron in their development of a coating to increase sand screen erosion resistance.

Scroll down to Learn More, or see SPE Paper SPE-210128-MS

Summary of Program and Results

-

A design optimized coated sand screen was developed that increases the erosion resistance of conventional sand screens.

-

Computational fluid dynamics and laboratory testing were conduced to determine the design optimization.

-

The program required designing a test fixture and flow loop to test the mesh filtraiton media

-

A coating was developed with rigorous testing at Delta Screens on mesh samples.

-

The screen has now been deployed and adopted with success in Gulf of Mexico and Angola.

-

The increased erosion resistance will improve completion life and recovery, critical in deepwater and other high reentry cost wells.

Business Need

-

Chevron worked with Delta Screens to develop a ‘design optimized coated sand screen’

-

Target applications were where cost effective increased screen life would improve recovery/well economics - deepwater, high rate wells with fines, and high re-entry cost wells

-

Computational fluid dynamics modeling and rigorous laboratory testing of mesh coatings and screen elements optimized the design

-

Installations in Gulf of Mexico and Angola have demonstrated improved erosion resistance

The test set-up was designed to efficiently test various coatings, working fluids, and flow rates for different durations.

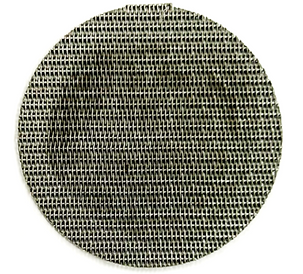

The set-up was designed to efficiently test various coatings, working fluids, and flow rates for different durations. Item 7 is the test screen mesh disc.

Filtration Media Testing

-

Flow rates and sand content replicated well conditions

-

Fluid modeling iterated with testing of multiple coatings

-

Numerous other areas of screen design affecting erosion were optimized as part of the process

-

Acid testing was also performed to confirm the screen was suitable for stimulation completions

Material Failure Point

-

The 25 micron dimension change is based on typical acceptance values for the mesh of +25 / -25 or for some operators at +25 / - 50, micron.

-

Coating eroded uniformly, acting as a homogeneous layer with the substrate.

-

Coating was found to not affect welds, burst/collapse, but section lengths were shorter.

Uncoated Filter Media

Failure Point

1.57 hours at 15 GPM

Aperture at 25 Microns

This represents a loss of sand control

Coated Filter Media

Failure Point

7 hours at 15 GPM

Aperture at 25 Microns

This represents a loss of sand control

Time to failure testing demonstrated the design objective of double screen life for the filtration media had been achieved, and more.

Results

-

Coatings outperformed expectations

-

10 Different coatings were erosion flow loop tested on mesh samples

-

An initial target was set to double the erosion life from uncoated screens

-

Several functional, fabrication, manufacturing and quality control requirements were addressed

-

Example requirements included burst/collapse, pre-conditioning host wire before coating, coating uniformity, coating thickness tolerance, inner/outer layers